4Machine operator resume examples found

All examples are written by certified resume experts, and free for personal use. Copy any of the Machine operator resume examples to your own resume, or use one of our free downloadable Word templates. We recommend using these Machine operator resume examples as inspiration only, while creating your own resume.

Learn more about: how to write a perfect resume

Performed various routine tasks to set up, operate, monitor, troubleshoot, and conduct preventive maintenance on assigned machines. Inspected parts to the specifications and made adjustments to maintain quality standards. Set up and operated production machines per established procedures and guidelines. Read and interpreted blueprints and diagrams to select, position, and secure machinery.

Monitored machines to ensure optimum running and meet daily production quota during each shift. Assisted with reducing setup time and weekly machine-hours factory-wide. Handled offsets within a short period according to standard safety procedures.

Managed operation and control of automated equipment and peripheral hardware reviewing production schedules, process procedures, specification, and performing sequential start-up. Conducted automated equipment set-up functions including loading of electronic components, raw cards, feeders, fixtures, stencils, and chemicals.

Coordinated warehouse operations by organizing complex projects, detecting machine malfunctions, and inspecting assembly components for defects. Verified Machine Control Data and kept the equipment in optimal operation. Maintained a safe and efficient workplace while ensuring production met or exceeded customer requirements.

Make a resume that wins you interviews! Choose one of these professionally-designed resume templates and follow 3 easy steps to complete.

Create a perfect resume in a few minutes

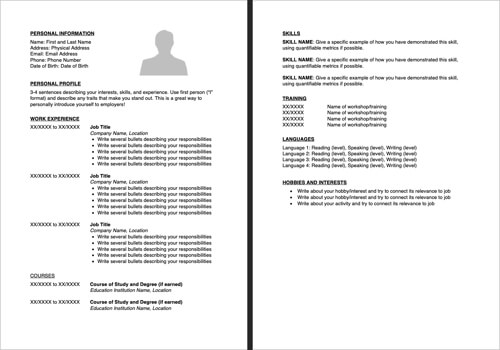

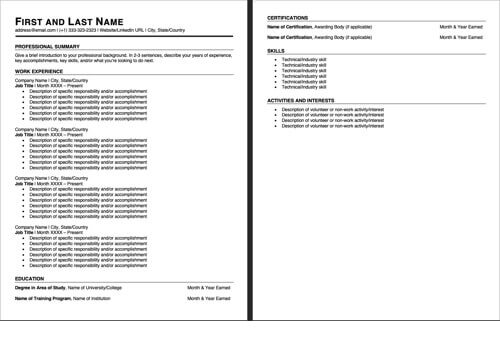

Download our American style resume template. Chronological resume format. Download a functional resume template.

Learn more about the differences between a resume and a CV.

Download our British/European style cv template. Similar to a resume but more commonly used in Europe, Asia and Africa.