14Manufacturing engineering resume examples found

All examples are written by certified resume experts, and free for personal use. Copy any of the Manufacturing engineering resume examples to your own resume, or use one of our free downloadable Word templates. We recommend using these Manufacturing engineering resume examples as inspiration only, while creating your own resume.

Learn more about: how to write a perfect resume

Built world-class manufacturing teams at the factory while implementing processes and best practices as well as identifying and mitigating risks to engineer high-quality products. Instrumented manufacturing requirements, quality standards, and product quality plan to ensure products meets the expectations of target customers. Improved field quality through effective investigations.

Collaborated with 5 department managers in analyzing systems and processes to identify and resolve various inefficiencies through automation. Automated multiple functions, including several assembly line sections, quality control, and data analytics.

Dynamic role requiring extensive engineering and leadership knowledge to drive multiple product development and manufacturing workflows to successful completion.

Increased productivity minimized lead time, and improved quality by implementing continuous improvement initiatives such as Lean, Six Sigma, and Quick Response (QRM) strategies.

Insightful position requiring active learning and adaptive skills to work directly under the supervision of the head quality engineer to facilitate the auditing and optimization of quality assurance processes.

Led the automated industrial projects and designed, programmed, tested, and commissioned small to medium engineering projects with all the stakeholders' responsible execution and implementation services.

Reengineered manufacturing tooling yield, reduced manufacturing costs, process time, and labor cost. Recognized as a technology expert for resolving SAP production and revenue-claiming/backflushing issues.

Worked closely with 6 production line managers in designing efficient production systems and machinery to resolve the various production hitches witnessed from time to time. Performed inspections on all production lines and implemented remedial actions that amplified efficiency and output quality.

Challenging role requiring leadership and project management skills to oversee a 5-man team of skilled professionals to delivery projects within budget and on time without compromising quality.

Liaised with a team of 10 in conducting in-depth analysis and automating various manufacturing processes to increase productivity, reduce costs, and maximize quality.

Make a resume that wins you interviews! Choose one of these professionally-designed resume templates and follow 3 easy steps to complete.

Create a perfect resume in a few minutes

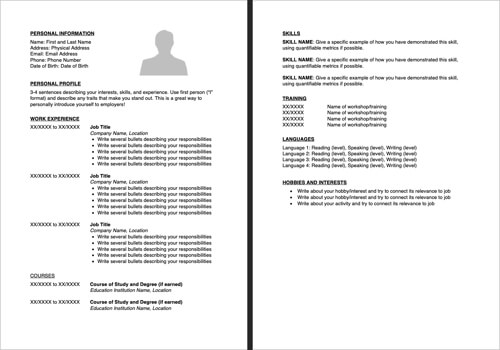

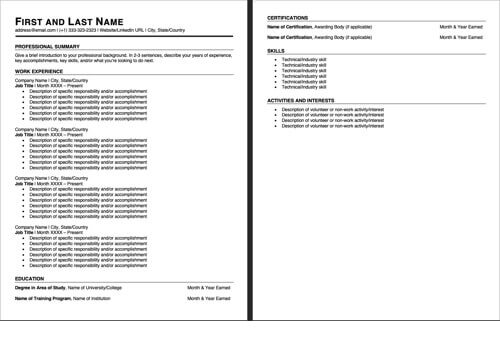

Download our American style resume template. Chronological resume format. Download a functional resume template.

Learn more about the differences between a resume and a CV.

Download our British/European style cv template. Similar to a resume but more commonly used in Europe, Asia and Africa.